By Heidi Bauer, CWP, P.E. and Yong Kim, Ph.D.

Reviewed by Ed Fritz, P.E. BCEE, James Hanson, P.E, David Oerke, P.E., BCEE

Reprinted with permission from the Fall 2020 issue of Digested News

The first thing an operator needs to know about polymer is it becomes a dangerous slipping hazard when introduced to water. Extreme caution should be exercised whenever working or cleaning around polymer.

Polymer in solution is viscous

(Figure 1), which means it is resistant to flowing. Because polymer solutions may be clear (no color), slippery areas are difficult to detect. Using absorbent material (such as cat litter) is the best way to clean polymer spills. Always consult the Safety Data Sheets (SDS) and the manufacturer’s instructions on how to safely handle each type of polymer.

Polymer is used as a flocculant for solids separation processes. The aggregation of particles into larger and more removable forms by applying coagulants or flocculants is necessary for efficient separation by clarification, decanting, sedimentation, filtration, thickening, and dewatering processes.

The terms coagulant and flocculant are often used interchangeably but they are not the same (Figure 2). Coagulants neutralize the surface charge of particles, which allows them to create small clusters of particles, called flocs. Flocculants make large flocs by bridging the small particles or flocs together.

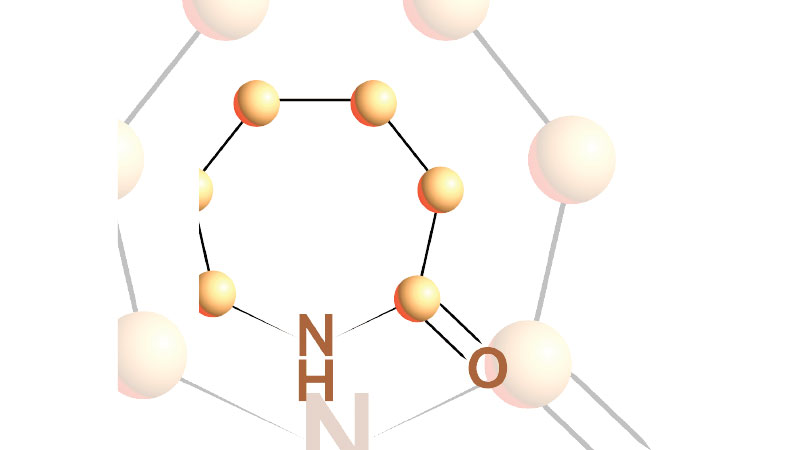

Polymers are effective as flocculants because they consist of long chains of molecules called monomers, which create bridges between solids particles (Figure 3). Polymers can have different charges, charge densities, and molecular weights. They also have a positive charge (a cationic) and a high molecular weight typically used for thickening and dewatering solids separation processes.

Applying polymer prior to a thickening or dewatering process is also called conditioning. Conditioning with

polymer is often a requirement for the thickening or dewatering equipment to successfully operate.

POLYMER TYPE

Polymer is supplied in three

different forms:

• Dry (Powder) Polymer (Figure 4)

o Typically contains up to

90% active polymer.

The remaining amount consists of residual water, buffers to control the solution pH, anti- caking additives to increase the shelf-life,

anti-dusting agents,

and small amounts of surfactants to facilitate the activation process.

o Requires more time for complete dissolution and activation than

emulsion polymers.

o Can be delivered

in 23 kg (50 lb) bags or

‘Super Sacks’ as large as

907 kg (2000 lb).

• Emulsion Polymer (Figure 5)

o Consists of micron- sized polymer gels emulsified in 30%

hydrocarbon oil.

o Depending on the amount of water in the polymer gels, the active polymer ranges from 20% to 55%, with the most commonly used being 40%.

o Can be delivered in

19 L (5 gal) pails, 208 L

(55 gal) drums, 1022 L

(270 gal) totes, or 11 400 to 18 900 L (3000 to 5000 gal) tanker loads.

o Mannich Polymer (Figure 6)

o Typically custom blended

for the specific application.

o Has a low active polymer content of 4% to 6%. Is delivered

in 11 400 to 18 900 L (3000 to 5000 gal)

tanker loads, and the transportation costs

are high unless the

Mannich polymer production facility is

located close to the

water resource recovery facility (WRRF).

POLYMER ACTIVITY AND DOSAGES

The polymer delivered to a WRRF is called neat and may include water, oil, surfactants, and other ingredients in addition to active polymer. The active content is the portion reacts with the solids. The percentage of active content is what’s being referred to when expressing a concentration of polymer. For example, a 1% polymer solution

has 1 gram of active polymer per 100 grams of polymer solution.

Dry Polymer has the highest activity levels in its neat form, so it requires the smallest storage containers. This saves money in the cost to ship and needs the least space to store but requires more equipment and time to prepare (or activate). The active content should be considered when assessing appropriate polymer dosages for solids processing systems.

The best way to think of polymer dose for thickening and dewatering processes is in active pounds of polymer per dry ton of solids (active lb/dry ton). In international standard (SI) units, active kilograms of polymer per dry tonne of solids (active kg/dry tonne).

A proper polymer dose for solids separation processes must relate the mass of the active polymer to the mass of the solids to which polymer is applied.

The calculation of polymer dose is as follows:

In international standard (SI) units:

This calculation can be applied to either neat polymer or polymer solution. For example, in US customary units:

• If the desired polymer dose is 10 active lb/dry ton, the flow rate to a rotary drum thickener (Solids Flow Rate) is 350 gpm, the rotary drum thickener feed solids concentration (Solids Concentration) is 0.75%, and

• If the active content of neat polymer (Active Neat Polymer Concentration) is 40%, then, using the equation provided, the Polymer Solution Flow Rate is calculated to be 0.03 gpm,

or 1.8 gph.

• Or, if the desired polymer solution (Active Polymer Solution Concentration) is 0.2%, then, using the equation provided, the Polymer Solution Flow Rate is calculated to

be 6.6 gpm.

HANDLING AND STORAGE

Dry polymer is hygroscopic (moisture-attracting) and should be stored in a

cool and dry area (neither above 40 °C [104 °F] nor humid). It has a shelf life

of over three years if unopened and properly stored. Once a bag is opened, dry polymer can quickly clump and become unusable.

Emulsion polymer tends to stratify (separate oil from water in the polymer gels) during storage, so a drum/tote mixer or recirculation pump should be used before the neat polymer is fed to the activation equipment. Emulsion polymer should be stored at the temperature range of 5 °C to 30 °C (41 °F to 86 °F) and dry conditions, preferably inside a building. If properly stored, emulsion polymer has a shelf life of six months. Should freezing occur, the product should be allowed to thaw thoroughly in a warm area and mixed well before use.

Mannich polymer must be used

within four weeks and should be kept away from both freezing and overly

warm environments.

POLYMER MAKE-DOWN

AND ACTIVATION

Emulsion and dry polymer in their neat forms must be activated in a dilute solution before being applied to a solids stream for conditioning. Dilution water is mixed with neat polymer to produce this dilute solution in a ‘make-down’ process (or a makeup process).

Make-down refers to the initial application of dilution water to neat polymer. Dry polymers are typically diluted to 0.2% to 1% active solutions for activation, whereas the purpose of a surfactant provided in neat oil-based emulsion polymer is to facilitate activation of the polymer in an aqueous solution and is often recommended at 0.5%. Mannich polymers are delivered as activated compounds, so the only goal for its make-down process is to produce a dilute solution for injection.

Aging After Make-down

Often, additional time is desired or necessary after the make-down process to complete the activation process. Aging (or maturing) starts from the moment polymer solution is discharged out of the polymer make-down system. Sometimes, the detention time of the make-down solution in the polymer feed piping is sufficient to complete full activation prior to injection. Other systems require a separate aging tank (for example, with a 30-minute detention time) to achieve full activation. Aging tanks are typically required for dry polymer systems.

Post-dilution After Activation

The optimal polymer concentration for activation is often not dilute enough to be the optimal concentration at the injection point, so it is helpful to have an additional post-dilution stage after the make-down and/or aging stages. Optimal concentrations for polymer injection solution can range from 0.1% to 0.25%, regardless of type.

Two-stage Mixing for Make-down

While polymers with higher molecular weights are more efficient in flocculation, they also present greater technical challenges in solution preparation

than lower molecular weight polymers.

The concept of two-stage mixing is

well established in the polymer make-down process for dry and emulsion polymer (Figure 7).

• First Stage, or initial mixing: High energy mixing at the initial stage. Proper wetting (for dry polymer) and high energy mixing during this stage will prevent ‘fisheye’ formation, including the prevention of fisheyes that occur on a microscopic level.

• Second Stage: Low energy mixing to minimize damaging the polymer molecules as they ‘uncoil’ out of polymer gels/particles. Much longer residence time is required for the second stage than the first stage. Second stage mixing can occur in

the same mixing chamber as the

first stage.

• Care must be taken to avoid breaking polymer chains through excessive mixing once activated. Damaged polymer chains will result in an increased polymer dose.

Emulsion Make-down Equipment

Although there are numerous emulsion polymer make-down systems available in the market (Figure 8), they can be classified into two types which differ in how mixing energy is delivered for effective polymer activation, mechanical and non-mechanical.

An advantage of mechanical systems includes the ability to provide high mixing energy (ideal for first-stage mixing), regardless of the fluctuation of WRRF water pressure. However, they may require more maintenance than non-mechanical systems.

Non-mechanical (or hydraulic) systems are easy to operate with fewer moving parts than mechanical systems. However, they require a dilution water booster pump to maintain the consistent incoming water pressure (minimum of 414 kPa [60 psi]), which is the source of the applied mixing energy.

Some make-down systems are designed

to include both mechanical and non-mechanical mixing.

Dry Polymer Make-Down Equipment

These (Figure 9) typically include a wetting system (including dry polymer feeders and

a rapid fill water dispenser), an aging tank, and a day tank for feeding the activated solution. A full batch system minimizes the number of tanks. For example, a mixer

could be programmed to provide both the initial high energy and the second-stage low energy mixing, and then the activated solution could be fed from this same tank. Other systems maintain separate tanks to optimize for each function.

INJECTION OF POLYMER SOLUTION

Because polymer solutions are so viscous, they are difficult to inject and disperse rapidly into the solids flow stream, especially if the concentration of the solids receiving the polymer solution is thick.

Different thickening and dewatering equipment units and applications require different polymer/sludge mixing mechanisms. Some equipment is designed with zones to accept the polymer solution and mix it with the sludge flow stream. Other equipment and applications perform better when the polymer solution is injected in the upstream piping of the thickening or dewatering unit.

There are many commercially available mixers with either static or mechanical mixing, so careful evaluation is required. Factors to consider are type of dewatering equipment, solids concentration, solids to polymer contact time, and polymer solution viscosity. For example, if solids contains higher than 4% solids, the static polymer-solids mixer may not be able to disperse polymer solution rapidly and uniformly into the solids. This can cause overdosing or under-dosing of polymer, leading to inefficient dewatering and wasted cost.

DILUTION WATER

The quality of dilution water has a tremendous effect on the efficiency of a polymer solution. Hardness, which represents a major portion of the ionic strength of dilution water, plays an important role in polymer activation. If hardness exceeds a certain level (such as 400 mg/L), it is strongly recommended to add a softening device to minimize the negative effect of hardness.

It is essential to reduce the chlorine level of dilution water to below 4 mg/L

to avoid damaging the structure of polymer molecules. When reclaimed water is used for the creation of polymer solution, it must be evaluated. Chlorine, suspended solids, turbidity, and dissolved ions in reclaimed water react with

polymer molecules and reduce the polymer’s effectiveness.

There is an optimal temperature range for dilution water. A water heater is recommended for dilution water below 4 °C (39 °F). Dilution water over 38 °C (100 °F) may damage polymer chains.

SUMMARY

Polymers are excellent flocculants critical for use as a solids conditioner prior to thickening and dewatering equipment.

A summary of common ranges for active polymer content (otherwise known as polymer concentration) is provided in Table 1. Optimal make-down and feed solution concentrations vary by the polymer product, type of injection

system, and the concentration and

other conditions of solids in the solids

flow stream. Conducting polymer optimization trials is recommended to determine the best concentrations for an individual system.

The type of polymer (dry, emulsion, or Mannich) will dictate the necessary systems and equipment for storage, handling, polymer solution make-down, and polymer solution injection. Due to the high viscosity, pumps that feed neat, activated, or post-diluted polymer solutions are typically high viscosity diaphragm pump, gear pump, peristaltic, or progressive cavity pump.

Operators can save money

on polymer by:

• Helping to select a cost-effective

polymer product.

• Calculating and monitoring

the polymer

dose in terms of active lb/dry ton.

• Appropriately handling and storing polymer in accordance with the polymer type.

• Ensuring proper mixing energy

and residence times for make-down and aging.

• Experimenting with polymer activation and injection concentrations to find the

• Optimal concentrations that minimize

polymer dose.

• Measuring and monitoring hardness

and other water quality parameters in

the dilution water.