The history of activated sludge goes back to the late 1800s and early 1900s when wastewater treatment was a trial-and-error

method and where biological treatment was a primitive science in this era. Generally regarded as a conventional norm for municipal wastewater treatment, the activated sludge process has drawn several engineering innovations, mostly post the implementation of The Clean Water Act of the 1970s. The Clean Water Act (CWA), established in 1972, is the most comprehensive environmental statute in the US. According to CWA, wastewater must be treated to meet certain discharge limits to protect the environment. Wastewater treatment is not only related to environmental sustainability. It directly connects with human health also. Wastewater generated from individual residents (society) and small-scale businesses is known as municipal wastewater. The advancement in the activated sludge process (ASP) has taken place from simply blowing the air in the waste mixture to the state of art nutrient removal. The wastewater community's current thrust to make the ASP carbon and energy-neutral/positive is appreciated globally, with several wastewater districts moving positively in this direction. For example, Central Valley Water Reclamation’s ongoing design and implementation in Utah to incorporate biological nutrient removal also encompass novel components such as phosphorus recovery in the sidestream treatment and energy recovery through co-digestion of food waste.

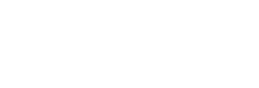

Several modifications and innovations have taken place in the activated sludge process over the last eight decades. The primary purpose has been to address expectations outlined in National Pollution Discharge Elimination Systems (NPDES) permit. Carbon neutrality, resource recovery, and process with smaller footprints are currently not required under NPDES permits. Nevertheless, the wastewater community has been proactive in these emerging areas of innovation to address climate change and resource recovery. In this regard, the current design in the form of the granular activated sludge process presents a leap forward in activated sludge process innovation/modification. The fundamentals of granular sludge technology are based on formation of compact granules (rather than loose flocs) to support multi-ecological compartments (e.g., presence and absence of O2) in each granule. Aerobic, anoxic, and anaerobic zones co-exist in granules supporting processes requiring the presence and absence of oxygen and oxidized forms of nitrogen. Additionally, granular sludge settles fast, resulting in much smaller plant footprints (Figure 1). Most importantly, due to the high retention of biomass in granules, mature granules allow growth and retention of slow growers such as anammox and DAMO organisms.

According to the United States Environmental Protection Agency’s (USEPA) 2016 report to Congress, an estimated 14,748 publicly owned wastewater treatment plants (POTWs) provide wastewater collection, treatment, and disposal to more than 238 million people in the US (USEPA, 2016). Unfortunately, many existing small and big POTWs have reached or about to get their expected life span. Additionally, rapid urbanization has forced many municipalities to look for treatment processes with smaller foot and carbon prints (e.g., anaerobic processes). Granular Activated Sludge Process presents a perfect opportunity to accomplish this mission. Fast settling of granules circumvent challenges associated with filamentous bulking and large space needed for secondary clarifier.

As stated earlier, granular sludge offers several advantages over its flocculated biomass, including: (1) significantly fast settling, (2) smaller footprints, (3) opportunity to support simultaneous nitrification and denitrification, and, most importantly, (4) resistance to external shock loads such as toxic loading and temperature changes. Each granule acts as a mini biofilm reactor where different types of bacteria synergistically work together to carry out various biochemical reactions. Results also show that granular sludge offers faster kinetics for contaminant removal, thus further providing the opportunity to design smaller bioreactors. As a result, the process requires less reactor volume, energy, and recycle pumping. Typical granule size could vary anywhere from 0.2 mm (minimum diameter) to few millimeters, with average size ranges from 0.6 mm to 3.0 mm (Figdore et al., 2017; Wei et al., 2020). The operational selection strategy includes shorter settling times where slow settling flocs are pushed out, and fast settling granules are retained. In terms of process microbiology, the diminishing settling time during process operation exerts selection pressure on the microbial community where they choose the path of “survival for fittest,” generate extra extracellular polymeric substances (EPS), resulting in more excellent adhesive properties than conventional flocs (Wei et al., 2020). Granules have a sludge volume index of about 30 to 50 ml/g instead of greater than 70 mL/g for conventional flocs (Dasgupta et al., 2019). It has been recently demonstrated by Wei et al., 2020 that treatment plants having enhanced biological phosphorus removing (EBPR) treatment process embedded tend to have granules naturally. Wei et al., 2020, in their survey of several EBPR plants in the US, found a wide range of granule abundance. These findings suggest that slight process manipulation in terms of aeration, feeding regime, and settler operation could significantly enhance granulation in existing treatment plants resulting in significant savings in process operation and sludge handling.

In summary, the granular activated sludge process is fast evolving and presents the future of activated sludge systems. The process allows integration of process engineering and process microbiology in a smart way to enable several biochemical reactions to co-occur. The ease of operation and current findings should provide the wastewater community the confidence needed to embrace granular processes.

Dr. Ramesh Goel is an environmental engineering professor in the Civil & Environmental Engineering Department at the University of Utah. He is very well integrated into the nation's wastewater community and considers the Utah wastewater community as his extended family. He has several granular reactors operational in his lab. For more information about the granular activated sludge process and other innovations and, in general, about nutrient managing strategies in wastewater treatment, please contact Dr. Goel at ram.goel@utah.edu.

Bibliography

Dasgupta, S. Haydee De Clippeleir and Goel, R. (2019). Short operational differences support granulation in a lab scale reactor in comparison to another conventional activated sludge reactor. Bioresource Technology; 271: 417-426

Figdore et al., (2018). Comparison of different aerobic granular sludge types for activated sludge nitrification bioaugmentation potential. Bioresour. Technol. 251, 189-196.

Wei et al., (2020). Flocs in disguise? High granule abundance found in continuous-flow activated sludge treatment plant. Water Research; 179: 115865